I can’t get my DOC200 to set. I was thinking my treadle plate was too low or my trigger bar too high, but now I’m not convinced either are the issue.

Is it too loose or will it not let you get the kill bar into position?

I’ve had both problems before. It’s usually a pretty easy fix.

I can get the kill bar into position but the trigger arm hangs free with quite a big gap between it and the arm of the treadle plate so it can’t be set as the trigger arm won’t stay in place.

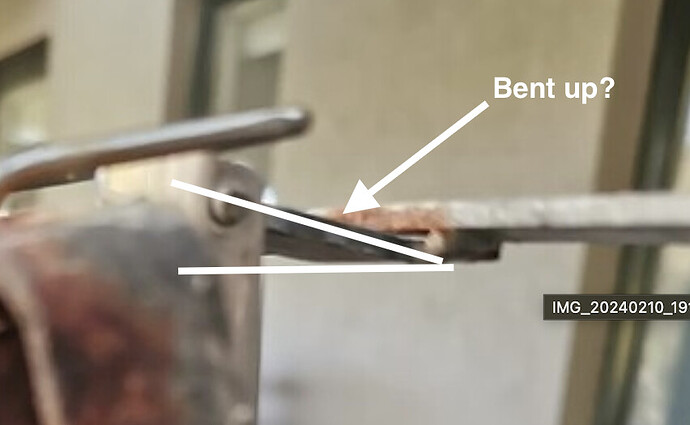

Raising the sear - the small metal square that the trigger arm sits against - might work. I use a size 2 or 3 square-head screwdriver and firmly tap the underside of the sear using a hammer. If you overdo it, you can use the hammer to tap the sear back down again.

It might be time for some WD-40!

I hope this helps.

Here is a copy of the video on how to reset the DOC200.“C:\Users\Kevin Mullane\OneDrive\Pictures\Pictures\List of files\Pest\Video\How to set up and service a DOC200 kill trap for conservation.mp4”

I can bend it down a tiny bit, but anymore then the kill bar doesn’t catch on the top of the swing bar. I’ll try and bend the arm a bit further down and raise the snub slightly. I also gave everything a good spray with WD40 yesterday to see if it allows anything to move better but it all seemed pretty smooth moving.

Thanks for all the tips, just really had to commit to a bit of bending and trial and improvement. It’s been in the garage all week, but in the end bait station got the rat in there so it’s now up in the chicken paddock.

I’m glad that you got the bugger.

Learning how to change the settings of your DOC traps makes a big difference. I was gifted 2 DOC 200s when I first started trapping, but I didn’t know that their settings could be changed. One was set at 220g and the other at 250g, which explained why my numbers were so low. Once I set them to 80g, the slaughter began!

I’ve got a problematic DOC200 as well. I borrowed it from a trap library today, all shiny and new, but efforts to set it ended with the trigger arm going past the sear (which looks suspiciously flat) and somehow getting jammed with the lower end against the wall of the trap and the upper end still holding the kill bar up but without the treadle involved. I assume that this is not some kind of new user-friendly modification because I couldn’t unset the trap again even by throwing things at the treadle!

I saw on this thread that I can ‘safety’ the trap by placing my screwdriver between the setting loop and box (since I don’t have a safety clip), which hopefully will let me jiggle the trigger arm free once the pressure is off, but I haven’t seen this problem before. Mostly when I have trouble with DOC traps it’s because the kill bar won’t stay up, not because I can’t get it to go down!

Anyone know what’s going on?

On the bright side, the local pests will be getting a good prefeed and can practice walking around on the treadle so they’ll hopefully be accustomed to it once it’s fixed and properly lethal again. ![]()

![]()

![]()

![]()

![]()

@christina.g - what you have mentioned in your post in that “lower end againist the wall and the upper end still holding the kill bar up” is in relation to the trap box sizing.

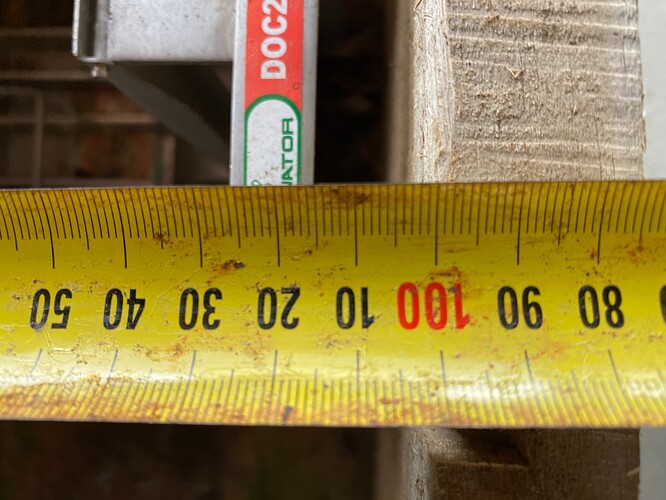

The trap box needs to be a minimum of 210 mm wide (NOT 200 mm) for a BT200 or a DOC200 trap to set off and the dropper bar swing back to release the kill bar.

How do we know this? In 2022 we purchased 100 traps in wooden boxes - and sent them all back to the manufacturer to be replaced! The box internal measurement was 200 mm and this only allows a minimum of 8-10 mm behind the trap for the dropper bar to swing and release the kill bar - it needs a minimum of 15-20 mm clearance for this to occur.

You could take the trap out and chisel out an insert into the side of the box - I suggest you take this information back to the trap library and get them to check all their other traps.

Attached are some photos - the first one is what the minimum width of a DOC 200 box (being 210 mm) 2nd photo - how many boxes today are being built - 200 mm wide (WRONG), 3rd photo - 200mm wide box only allows 8-10 mm gap at back of trap, 4th photo - should be minimum of 15mm behind trap and box.

Let us know how you get on with this information.

Thanks @eric007! I will take my measuring tape out tomorrow and confirm, but I think your 200mm-box pictures look very much like the trap I’ve got.

Yes, this was the problem! The interior measurement was only 205mm instead of 210mm. I couldn’t do the chiseling part (because one of the screws holding the trap in place was partly stripped and I couldn’t unscrew it to remove the trap), but I’ve returned it to the trap library for repairs and got a replacement instead. Thanks @eric007 ![]()

@christina.g - unfortunately we don’t know how many other traps around the country may suffer this minor indiscretion (major trap failure) - and not capture any “pesties” that may have visited.

Interesting that the trap supplier came back to us with a modification to the original traps - (see attached picture) this must have been a lot of effort - it worked but it modified the timber integrity!

We accepted new trap boxes - 215-220 mm wide.

I had this problem in one of my DOC 200 double-sets. 1 trap fired normally, but the second one couldn’t. I had been given some DOC 150’s, so I swapped it with the DOC 200 and everything works fine. The gap between the wall and the back of the 150 allow me to put larger lures in there that don’t interfere with the kill-bar. An egg or a golf ball stands out a mile and it’s especially appealing if it’s put on top of a fake nest. It’s also a good spot to place a dead rodent or a mustelid, especially at this time of year.

I liked this configuration so much, that I made a DOC 150 double-set in an old DOC 200 double-set. You have more room to work with, it’s easier to set 150’s than when they’re in a DOC 150 double-set, they’re a bit lighter to move, and I haven’t had any problems with sympathetic-firing, which affects quite a few DOC 200 double-sets.

I’d pay extra for 230mm wide tunnels to avoid the frustration of traps not having enough space to fire properly. If you have tunnels made for you, it couldn’t hurt to request this, because that’s a very small increase in the amount of timber and it’s a very small alteration for the builder of tunnels to make.

Not sure if this is the best pace for this post – but here goes

We have about 10 doc250s and 12 doc200s spread around 70 acres of the Park – 250s around the perimeter and 200s around the central roads targeting hedge hogs.

We have recently been gifted 11 doc200s (and a multitude of other control equipment) by NZTA following the completion of a skink release project relating to Stage 1 of the Takitimu North Link road project. The doc200s have been set up to be very sensitive and are regularly catching mice and rats. The control area was just 1 Ha around a central skink release pen and one of our elderly friends has taken on the task of checking them each week. But old age is not kind to old hands and he has insufficient strength to reset the traps by hand or with the standard doc setting tool – he has to let me know what traps have been tripped and I make a quick trip to remove the animal and reset the trap.

Can anyone suggest a more user-friendly setting tool that is easier to engage with the top frame of the trap and has a more user-friendly operator handle.

I don’t know of a tool that he could use to arm DOC traps, but he may be able to assist your trapping efforts in a different way. You could remove the DOC trap from a few tunnels and replace them with a pair of T-Rexes, which require way less strength to set than a DOC trap. Inside a DOC double-set tunnel, there would be enough room to house 4 T-Rexes. There might also be room for a few mousetraps, too. Screw the traps down, fill the bait cups with tallow/dripping, my weapon of choice, and he should be able to knock off quite a few predators.

The cost of 4 T-Rexes is usually less than the cost of a DOC 200, and my T-Rexes kill a lot of predators before they have to be replaced. I’ve humanely killed a few hedgehogs in T-Rexes before, but there must be somebody out there with more experience killing them with snap traps.

Cheers.

Hi Mindie

I have only just seen your post I make two different tools that can be used on 200’s

the smaller one does not give any mechanical advantage but gives something secure to grip, $7

the larger one is half the weight of the DOC version and works a bit better $25

also make a better safety clip for the 200 $3

I’m in Tauranga and they can be picked up from home 07 5440885

cheers

Dave

Thanks Dave

This site is a fantastic source of information – just what I was looking for – I will take two of each tool and two extra safeties

I recall you had a better solution for setting Sentinels which I would like to review – my ten traps are gather rust in the shed – but now the pines are flowering, I could put a few out if I had a user friendly solution to operate them – my favourite possum trap, but most people are scared of them

I will give you a call

Cheers

Mindie

Thanks for your response WFW

I have decided to retain all of the Stage 1 release protection equipment – it may be useful for the stage 2 project although that will be expanded to 5Ha.

I believe the 1ha stage 1 area is intensively trapped with the 11 doc200s and so long as we keep them active, well baited and well checked – they should keep most animals under control. I believe the contractor that operated the Stage1 control system slipped up badly by not placing a few cat traps in the area – in fact we caught a huge feral cat in a doc200 a few days ago – a large cat has a long reach that was able to touch the treadle plate – not a nice job to find the box and deal with the animal humanely. I will install a few SA2 or possum master traps very soon.

The uncontrolled APEX predator must have done a lot of damage during the last two years – I hope it didn’t get any skinks.

We operate a large number of rat snap traps within the Park – but the team will not touch anything but the Kness Snap-e